Do you know anyone who might be interested?

For one of the largest employers in the Olomouc region, we built a fully automated and robotic powder coating line. Due to its high capacity, the robotic application was equipped with a seventh axis, enabling efficient coating of complex-shaped products at a speed of 2 m/min. The new technology, funded by grants, ensures efficient and precise coating with minimal human intervention.

| Customer | ZLKL, s.r.o. |

| Year of Realization | 2023 |

| Technology |

|

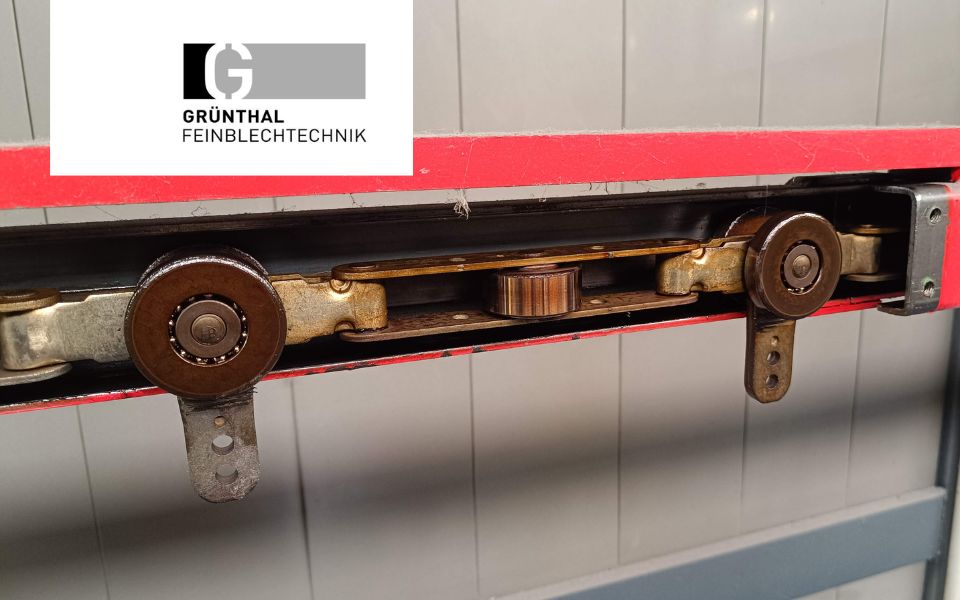

The customer requested a multimetallic robotic powder coating line meeting high surface finish requirements.

The line was designed and built for large-sized, thin-walled products and the automotive segment, allowing for coating without human intervention. Due to its high capacity, the robot was equipped with a seventh axis, enabling efficient coating of complex-shaped products at a speed of 2 m/min.

Show more information - Coating facilities

View productDo you know anyone who might be interested?