Do you know anyone who might be interested?

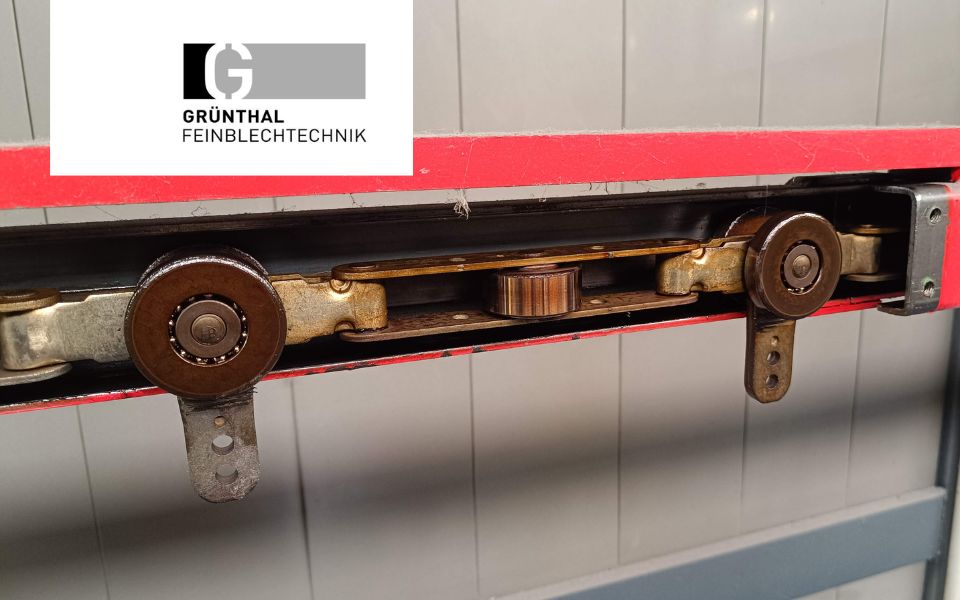

At the turn of 2019 and 2020, we completed the implementation of powder coating facility for a major producer of racking and storage systems. The coating line is equipped with the Power&Free conveyor with the tact of 3 min/cart. Distribution of colour is ensured by the PowderVision powder center equipped with the system of recycling of colours from the cyclone with automatic dosing back to circulation.

| Customer | KOVAL SYSTEMS, a.s. |

| Year of Realization | 2019 |

| Location | Beluša (SK) |

| Flow profile | 1.000 x 2.200 x 4.500 mm (w x h x l) |

| Technology |

|

The coating line is equipped with the Power&Free conveyor with the tact of 3 min/cart. Continuous 5-stage chemical pre-treatment prepares the surface before coating.

Coating itself is provided by 40 SAMES KREMLIN guns in two plastic coating booths. This solution allows a quick change of colours, which was one of the customer's basic requirements. Distribution of colour is ensured by the ITS PowderVision powder centre equipped with the system of recycling of colours from the cyclone with automatic dosing back to circulation.

Throughout the coating process, the products pass through the drying oven and curing oven and also through the cooling zone for effective cooling before they are taken down.

Automatic line control is provided by the HiVision control system with the eSaver module for efficient power management.

Show more information - Coating facilities

View productDo you know anyone who might be interested?