Do you know anyone who might be interested?

We have constructed a combined two-track coating line with wet and powder coating booths. The delivery included an air handling unit with the capacity of 20 000 m³/hour and automatic blasting machines. The entire technology is electrically heated.

| Customer | Blaze Harmony s.r.o. |

| Year of Realization | 2022 |

| Location | Lipník nad Bečvou (CZ) |

| Flow profile | 800 x 1200 x 2000 mm (w x h x l) |

| Industry | Manufacture of boilers |

| Technology |

|

The coating line can powder coat bodies of the weight of 200 kg and the wet node can paint even bodies of the weight of several tonnes. The technology was financed by a European Union grant.

Pellet boilers are nowadays a matter of design and quality of coating plays an important role; that is why we used the innovative application technology of Sames bells for the coating booth. The technology will ensure perfect coating with even layer of powder over entire surface of the products.

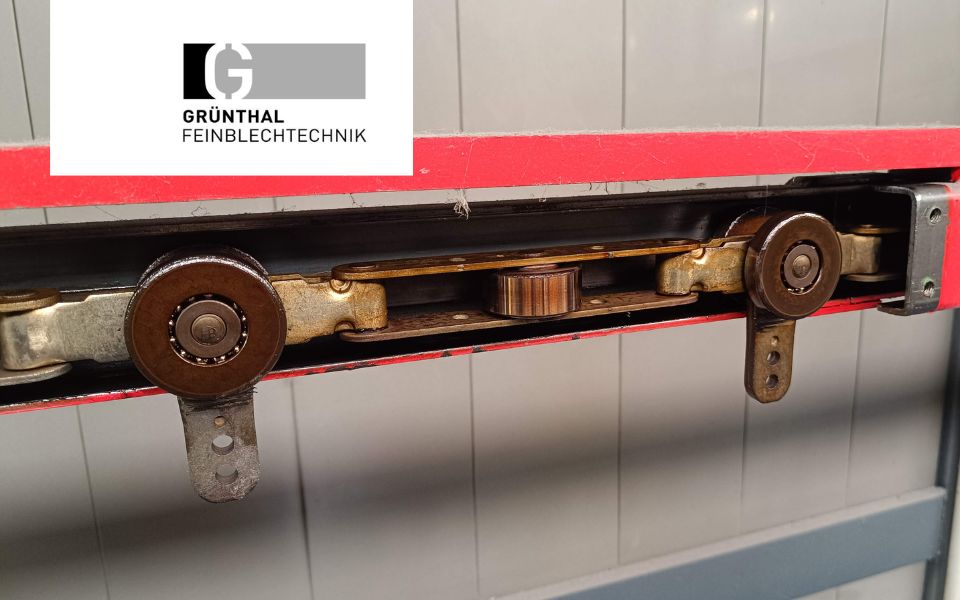

As handling of big and heavy parts is complicated at nominal speed of 0,5 m/min, the coating line is equipped with a suspension system – using the LED bar indicator that displays the most effective suspension of the products in a row.

Show more information - Coating facilities

View productDo you know anyone who might be interested?