Do you know anyone who might be interested?

A domestic manufacturer of fittings, valves and gates has been struggling for a long time with the problem of how to effectively coat valves.

| Customer | Jihomoravská armaturka spol. s r.o. (dnes VAG) |

| Year of Realization | 2015 |

| Location | Hodonín (CZ) |

| Technology |

|

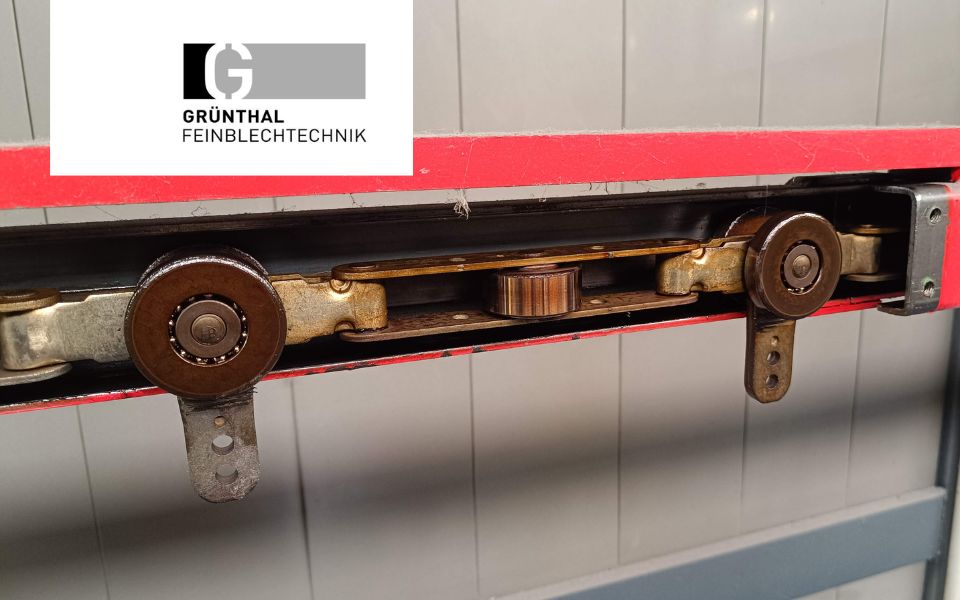

The valves need a thick layer of epoxy powder coating, while they also require a transparent layer of polyester paint to ensure UV resistance. Until now, coating has been done separately: The epoxy layer was applied in the fluidised bed, then the paint was fired, and the polyester paint was applied in the coating booth. This manufacturing process takes a long time and requires manual handling of the product. We designed a new coating facility with an emphasis on automatic handling of the part and firing of epoxy and polyester paint in one step. The design of the coating facility was accompanied by simulations and tests of handling theproduct with a weight of 140 kg.

Show more information - Coating facilities

View productDo you know anyone who might be interested?