Do you know anyone who might be interested?

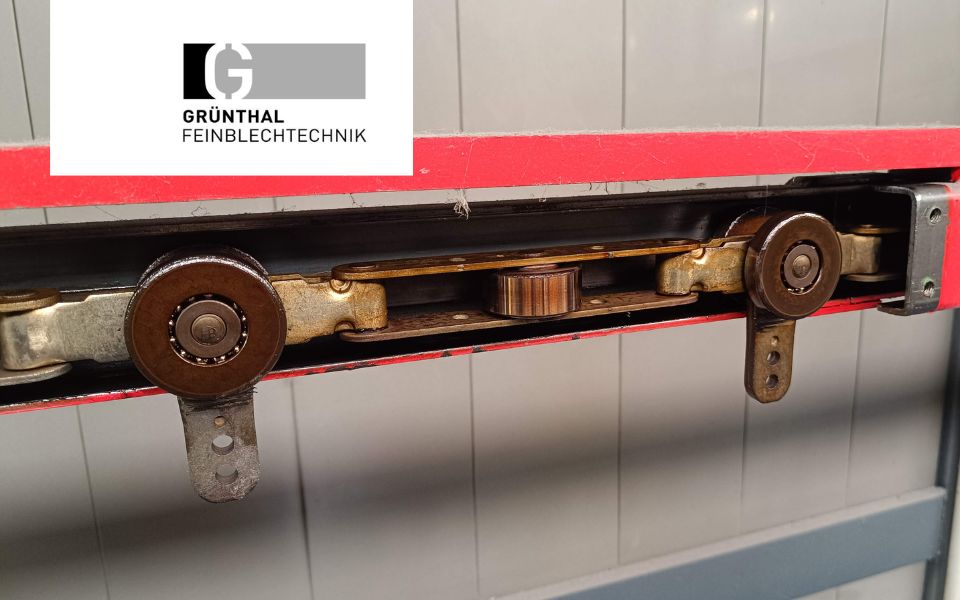

We have built a powder coating facility with tact spray chemical pre-treatment and P&F conveyor for treatment of aluminium profiles for a company producing shading technology. The coating line is one of the largest and most modern in the Czech and Slovak Republics.

| Customer | SERVIS CLIMAX a.s. |

| Year of Realization | 2021 |

| Location | Vsetín (CZ) |

| Flow profile | 500 x 1700 x 7500 mm (w x h x l) |

| Industry | Production of shading technology |

| Technology |

|

The shading technology producer outsourced coating of its products at external suppliers, thanks to the new coating facility the capacity has increased and overall logistics has improved.

It is a unique technology where the surface of aluminium profiles of their length of 7.9 m can be treated in façade quality. The investor put great emphasis on the line capacity and quality of coated parts without sections plus the possibility to modify the line in the future and further increase its capacity. Several coating tests were performed on different profiles before the result was approved by the investor. ITS experts were working on the project and the coating facility was constructed in a very short time despite the fact that current Covid situation made it very difficult. For the interim period - before the large coating facility was built - we built a small paint shop in the same hall.

Show more information - Coating facilities

View productDo you know anyone who might be interested?