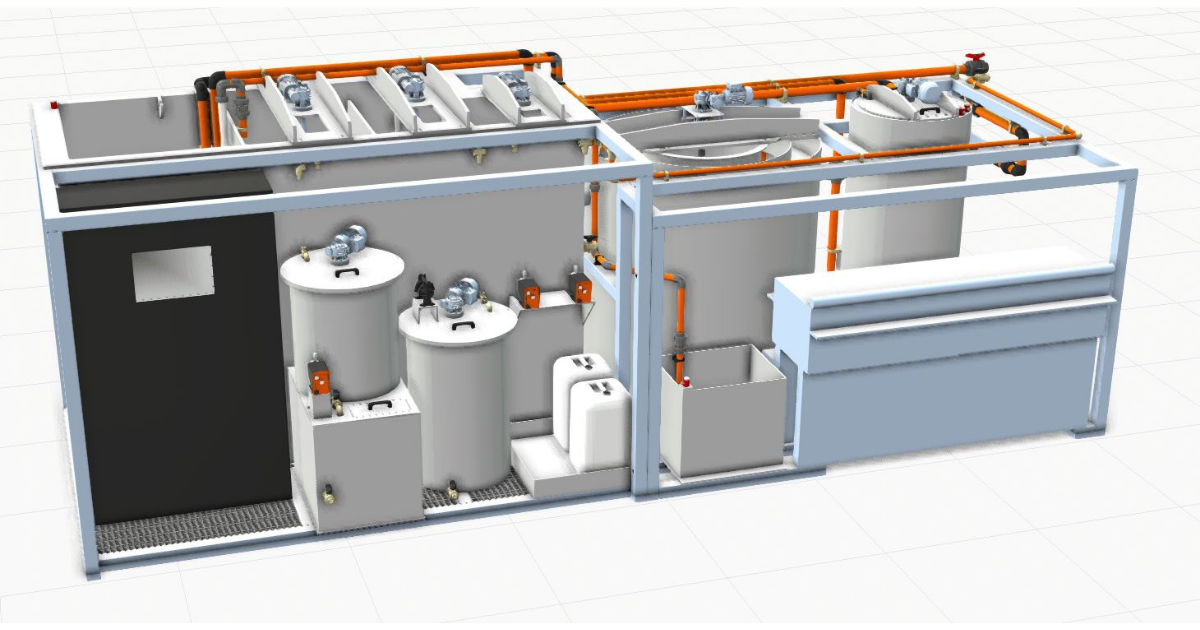

We have implemented a fully automatic through-flow neutralization station for a leading Czech supplier of components for the German manufacturer of CLAAS agricultural machinery.

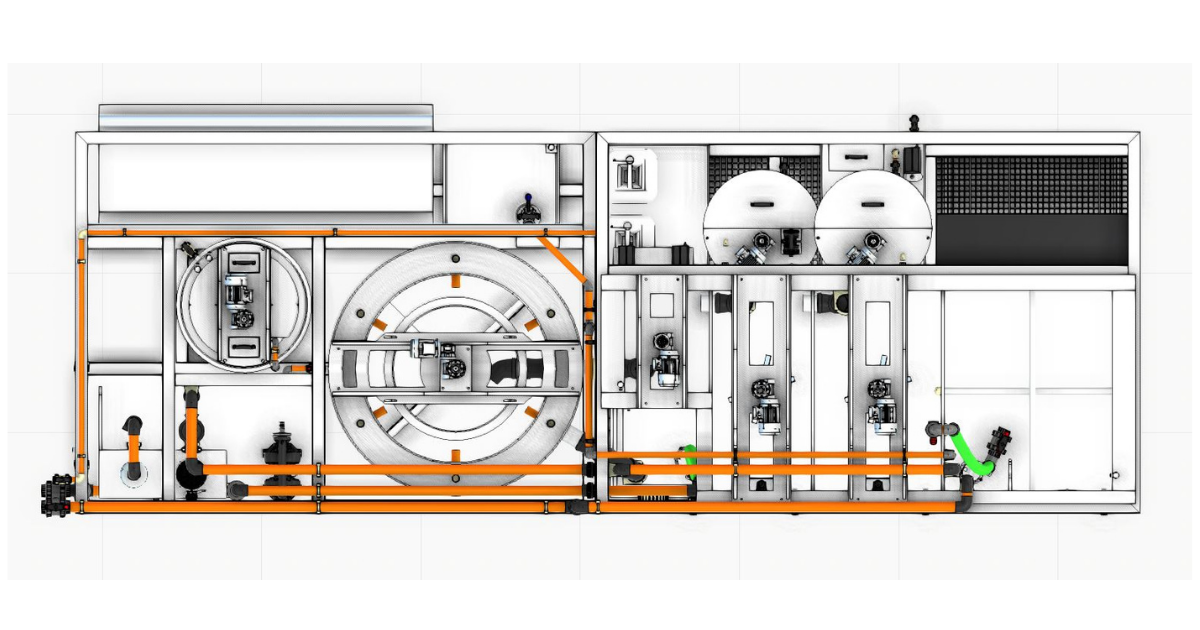

Surface pre-treatment in the highest quality, including zinc phosphate application, cataphoretic coating, and waste-water treatment, requires a comprehensive solution. The neutralization station allows up to 1,500 m3 of waste water to be treated on a monthly basis. In addition, the neutralization station capacity is automatically adjusted based on the requirements of the technological system.

The torage tanks concept makes it possible to operate the technological system continuously even during the regular maintenance of the neutralization station.

The quality of water at the outlet is constantly monitored by the HiVision automatic measuring systems. Parameters that cannot be measured continuously on-line are processed by our SQI laboratory in compliance with the applicable regulations and standards. Data is automatically stored in the database system and can be retrieved at request.

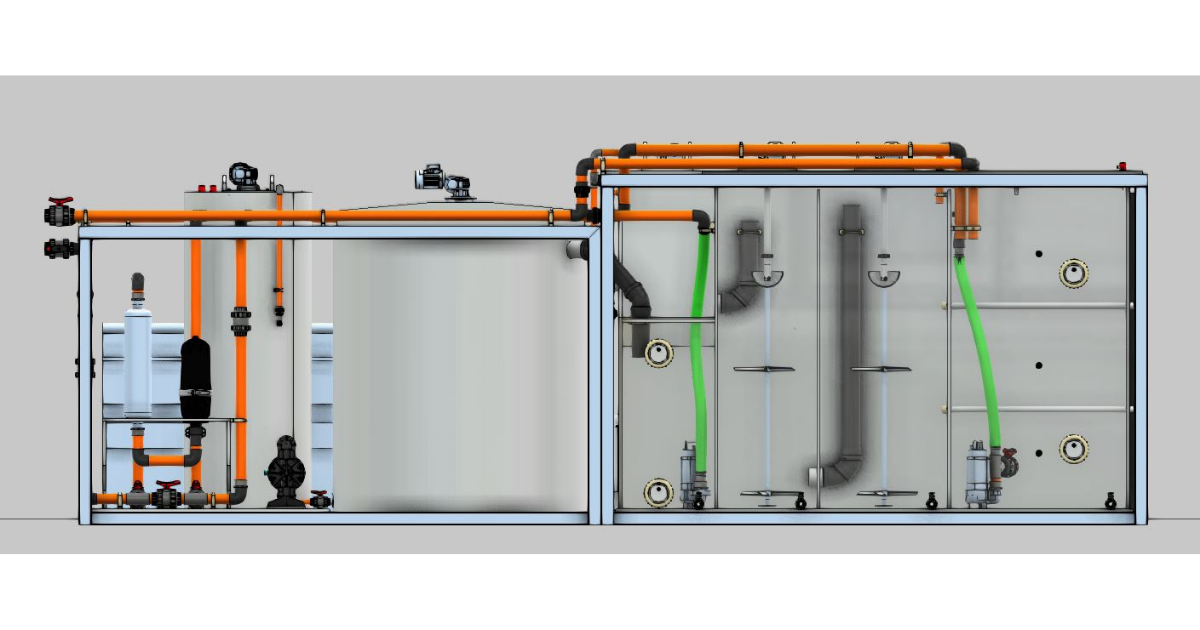

The design of the neutralization station is modular, allowing its complete testing before delivery to customers. There the module is connected to the required energy infrastructure and is ready for operation. This concept reflects the new trend in the construction of modular factories or robotic cells.