Coating facilities

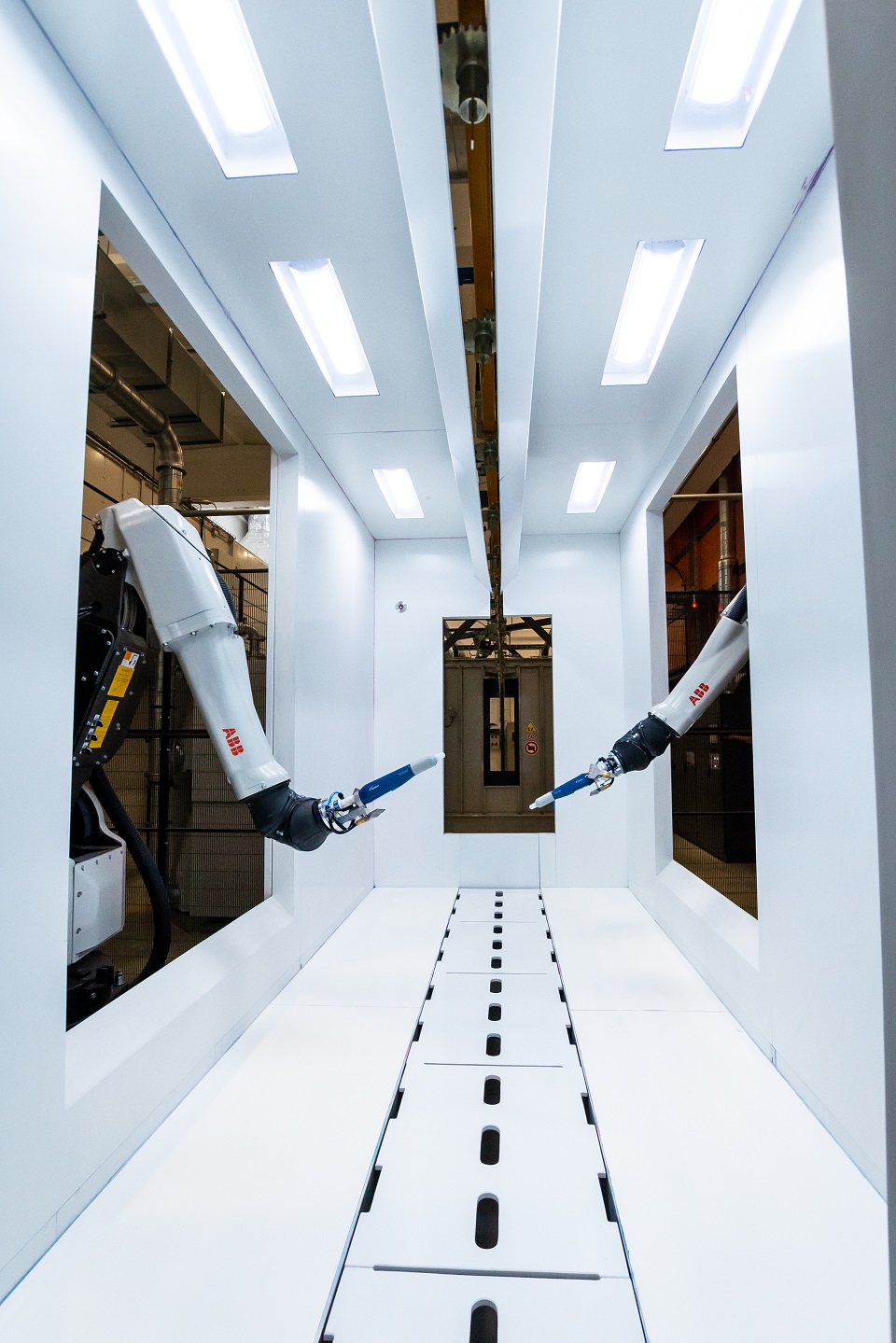

Robotic coating application ArtiCoating

Robotic applications represent a key step towards more efficient and reliable manufacturing. Thanks to its precision and ability to work in diverse environments, it is an ideal solution for automating repetitive tasks.

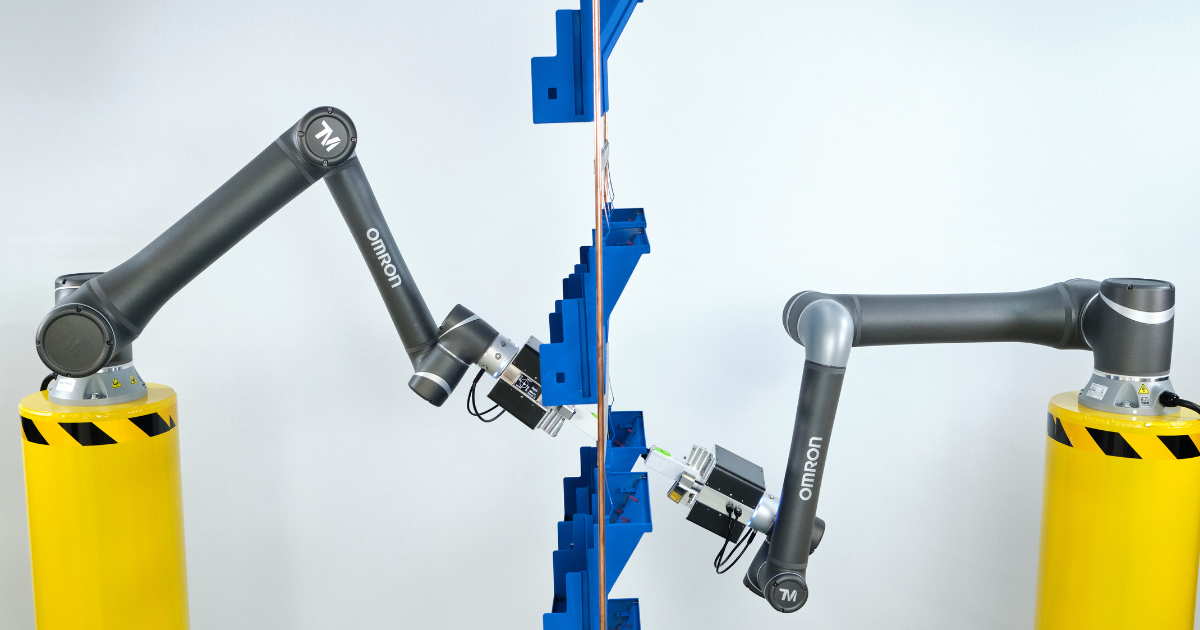

Robotics is not just about the robot itself as we know it. It can encompass a wide range of technologies, including manipulators, linear axes, and mobile robots. Moreover, there is the concept of collaborative robotics, where machines work alongside humans, with the robot taking on certain tasks while the human oversees other parts of the process. It is essential to understand that the robot is just one of many elements in the entire automation chain.

ITS offers the implementation of a variety of automated processes, such as painting, uncured paint layer measurement, or hanging, uploading, and masking, whether for new paint shops or existing facilities.

Thanks to our exclusive partnership with Han’s Robot, we offer innovative solutions for automated coating with ATEX certification for explosive environments, along with a wide range of other applications.

Why choose the ITS collaborative robot?

• Exclusivity in the EU and strong partnership – we are the only provider offering our own certified coating robot with direct support from Han’s Robot

• ATEX certification for explosive environments – suitable for zones 22/21, 2/1

• Versatility – supports both powder and wet coating, with flexible integration into various technologies

• Comprehensive offering – we supply complete turnkey solutions as well as standalone hardware

Robotic and Manual Painting in One with ArtiCoating®

Maximum Flexibility and Easy Integration

We offer a solution that combines the benefits of robotic and manual painting, with the option to switch seamlessly between both modes. With a special holder, the painting process can be quickly adapted to different product types without losing efficiency. This collaborative system is ideal for companies seeking maximum flexibility in handling various shapes and sizes of parts.

Key Benefits:

- 7th Axis for Maximum Mobility – The robot offers flexible movement, allowing precise painting of even complexly shaped parts. Available in the basic version.

- ATEX Certification for the EU – Our equipment is certified for use in explosive environments, ensuring safe operation even under the most challenging conditions.

- Easy Integration – The robotic system can be quickly and seamlessly integrated into existing paint lines without requiring modifications to control systems. Additionally, warranties on existing equipment remain fully intact.

- Simple Operation – The intuitive interface enables easy operation, even for operators with no prior robotics experience.

- Robust Design – The all-metal design of the robot ensures a long service life and high durability, even in demanding industrial conditions.

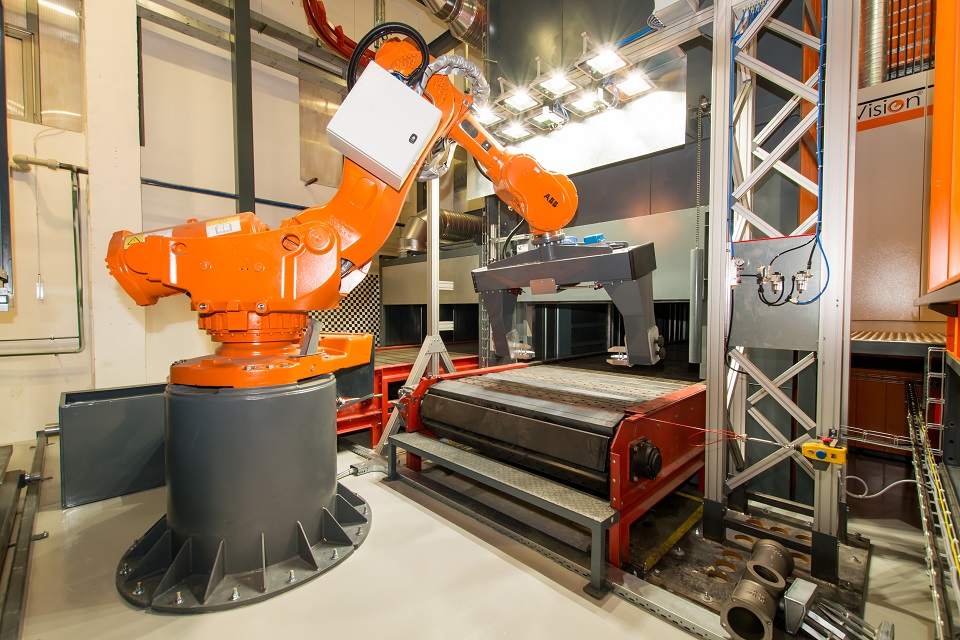

Robotic Paint Layer Measurement with ArtiDeepControl®

Measurement Before Curing

By using non-contact measurement of the powder coating layer immediately after application, the spraying parameters are adjusted based on evaluated data so that the layer meets precisely defined requirements. All of this occurs while the paint shop is in full operation.

- Measurement of uncured powder coating directly behind the booth

- Fully automated process with automatic sensor calibration

- Unlimited number of measurement points on a single product

- Automatic correction of spray gun settings in the booth

- Storing of measured data for each product in a database

Why Choose Robotic Coating?

- Precision and Production Speed: Robots can apply paint with consistent quality and in a short time, boosting overall productivity.

- Operation in Hazardous or Unsuitable Environments: Robots can handle dusty or chemically aggressive conditions, making them ideal for demanding production environments.

- Minimizing Human Intervention and Increasing Reliability: Automating the process eliminates human error and improves consistency of results.

- Enhanced Efficiency and Quality: Robotic automation achieves consistent results with minimal errors.

- Safe and Reliable Operation: Robotic systems eliminate the risk of workplace accidents and ensure continuous operational reliability.

- Cost Reduction: Automating the painting process saves time and resources, leading to lower overall production costs.

Efficient Automation for Your Production

When implementing robotic painting, it is necessary to test the entire process to evaluate the economic feasibility of the design and ensure adherence to required parameters. In our development center, we conduct tests for the entire process.

Are you interested in robotic coating?

Do you have a question or a specific request? Write to us.

Do you know anyone who might be interested?