Coating facilities

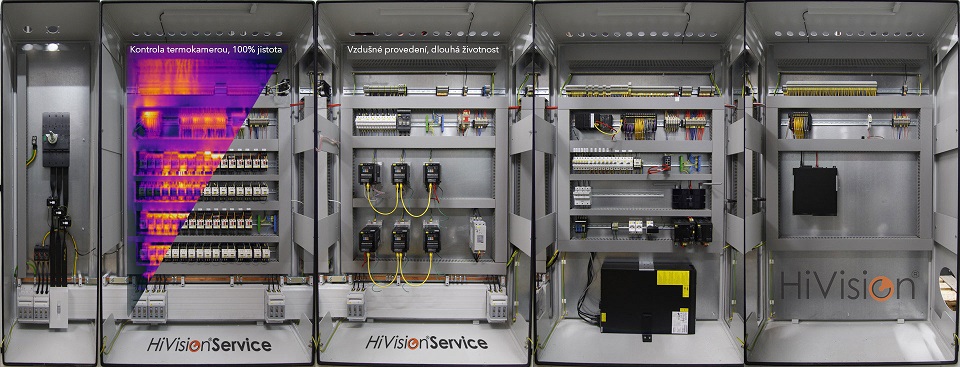

Control systems HiVision

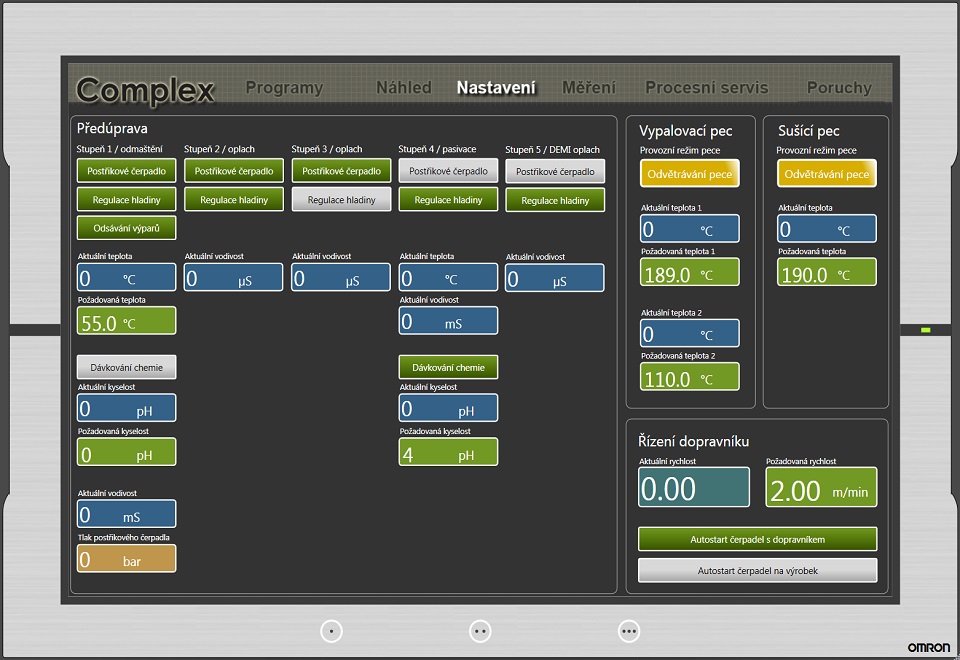

For the control of the painting process, we use the latest knowledge from the plants and always adapt the control technology to the customer's requirements. The HiVision control system developed by us is a comprehensive management, control and service system for your paint shop.

HiVision is a unique system developed for over 15 years, enabling comprehensive control of technological units, including robots and material handling. The ability to freely expand control modules with additional functions or customize the system to specific needs makes HiVision the best available solution on the market

Key advantages:

- Modules and Customizable Solution – the system can be tailored to customer-specific requirements

- Remote Management – diagnostics, adjustments, and service without physical intervention, reducing operational costs

- HiVision Cloud – storage and analysis of operational data to optimize efficiency

- Artificial Intelligence – predictive maintenance and automatic detection of abnormal conditions

- Industry 4.0 – full integration into smart factories with automated control

- Big Data Analysis – unified data for better insight into costs and operational efficiency

General Advantages

- Technological Openness and Compatibility – integration of various brands of robots, PLCs, and other devices, including Siemens, Honeywell, OMRON, ABB, KUKA, and ITS Robot

- Turnkey Solutions – from design and implementation to after-sales service

- Efficiency and Savings – optimized consumption of energy, chemicals, and water

- Large Graphical Interface – clear and intuitive control system

Pre-treatment

- Precise Level and Chemical Parameter Measurement – sensors resistant to dirt and high temperatures, offering easy maintenance and high accuracy even in demanding conditions

- Smart Chemical Dosing – dosing based on actual consumption and part size

- Efficient Operation (€SAVER) – automatic regulation of water, chemical, and energy consumption

- Rinse Water Management Based on Conductivity – saves water while maintaining process quality

Coating Booths

- Automatic Coating Program Change – the system adapts to the product and minimizes downtime

- Exhaust Control with Frequency Converters – more efficient booth cleaning and reduced energy consumption

- ERP and Database Integration – better job tracking and preparation for painters

- Remote Coating Program Configuration – faster response to production changes

Ovens

- PID Temperature Control – stable conditions for various paint types

- Automatic Doors – minimize heat loss and dust entry

- Camera-Based Curing Monitoring – real-time process tracking for optimal results

- Intelligent Electric Heating – smooth regulation of energy consumption

Continuous Conveyor

- Automatic Conveyor Jam Monitoring – minimizes damage to equipment

- Frequency Converters for Speed Control – performance optimization based on product type

- P&F Conveyor – real-time product tracking and motion adjustment

The HiVision system combines advanced technologies with sustainable solutions, delivering cost savings and increased efficiency in coating lines.

HiVision is a registered trademark of ITS.

Download

Are you interested in HiVision control system?

Do you have a question or a specific request? Write to us.

Do you know anyone who might be interested?