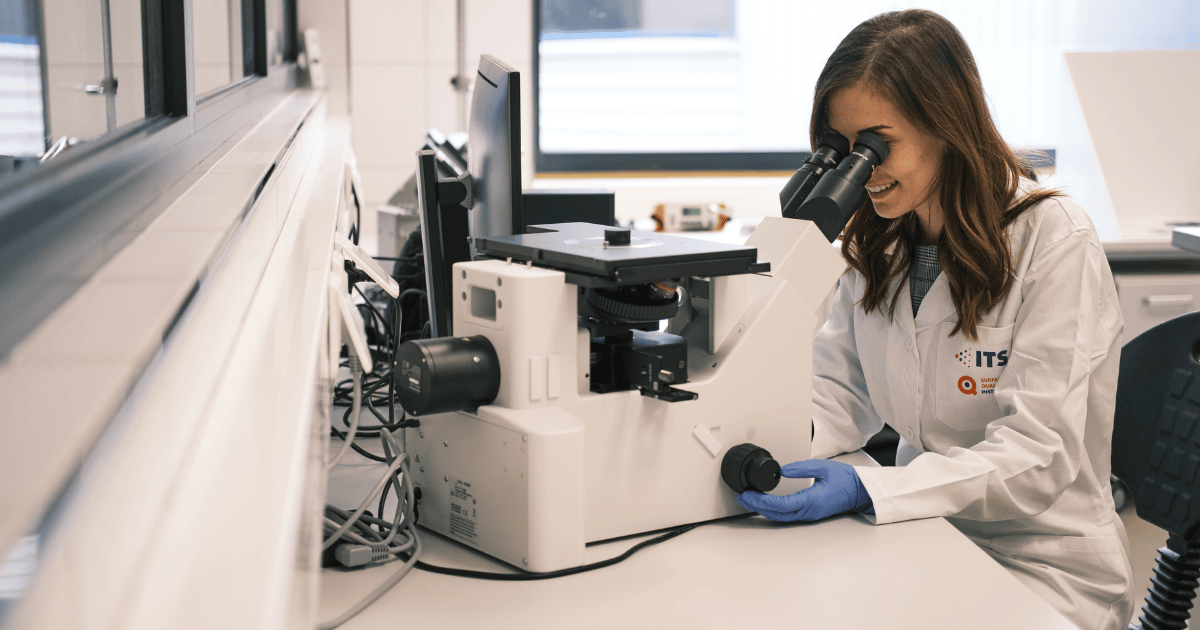

With the production and development of technological units for surface treatment and coating comes the need for testing technologies and products. As the number of request from our clients grows and innovations develop, there is also a need to not only be one step ahead, but also to think ahead. That's why we built our own Surface Quality Institute (SQI) laboratory with state-of-the-art technical equipment including a metallographic microscope and two salt chambers.

Having our own laboratory is a tremendous advantage in our industry, especially for ensuring compliance with correct procedures and providing solutions in case of defects. Our goal is to respond to feedback from the factories and to the requests our clients approach us with. In 2020, a new headquarters was opened in Brno Slatina, expanded with new premises with four laboratories designed for further research.

The first laboratory is mainly used to support our chemistry division. We analyse the operational parameters of baths, determine the surface weights of titanium and other conversion layers. However, we can also advise on the selection of the right degreaser or check the quality of sealing for anodised layers. A separate chapter is the neutralization station process. Protection of the environment and related wastewater treatment is an important topic for us. Therefore, we do not only determine the parameters of the outlet waters, but we also carry out the entire neutralization process and recommend suitable customized solutions.

The second laboratory is equipped with instruments and equipment for determining the mechanical and protective properties of coatings. We perform tests according to ISO, ASTM, Qualicoat or GSB standards. The microscope also serves a significant purpose. Through microscopic analysis, we can identify the causes of defects and suggest suitable solutions to problems discovered. This is particularly beneficial for anodizing plants.

In another laboratory we focus on corrosion testing. Primarily, tests in a neutral salt spray are requested, but we are also able to perform a condensed water tests. You can also contact us with requests for cyclic tests, acidic salt spray test and many other exposure tests.

In our last laboratory, we are able to simulate the pre-treatment and painting process, thus fine tuning technological procedures for specific paint factories. We can work directly with customer samples in our environment and correctly adjust the technological process without disrupting the production, which is a great advantage.

In addition to the above activities, we cooperate with external laboratories to meet the requirements of all customers. Please do not hesitate to contact us for any analysis, testing or assistance with defects.